When it comes to handicap access, there are long ramps, short ramps, threshold ramps, folding ramps, portable ramps, temporary ramps, permanent ramps, modular ramps, automobile ramps, residential ramps and commercial ramps.

That is just a quick list of ramps HME providers can consider adding to their business inventory. But the most common type of ramp is fast becoming extinct for most HME providers—the wooden ramp.

Throughout the past 25 years or so, aluminum has emerged as a superior choice over treated wood for many good reasons. Still, experts say, wood often persists in the public perception of wheelchair ramps. The challenge for HME providers considering the ramp business is to take a bite of revenue out of those old wooden ramps.

It’s a job that has already been started by aluminum ramp companies such as EZ-ACCESS, a firm founded in 1984 and headquartered in Algona, Wash.

“It’s been a long, hard process,’’ said Judson Branch, vice president of sales for EZ-ACCESS. “We’ve gone from being a cottage-type company with a niche product … to becoming mainstream medical equipment. The thought process of the ramp being made of wood has changed. A prefabricated ramp like ours is now fully accepted by funding organizations and the public itself.”

Providers have the job of driving the aluminum message home to consumers.

“Dealers have to tell that story—don’t think about wood,’’ said Karen Riker, marketing director for American Access, a ramp manufacturer based near Memphis, Tenn. “And as a matter of fact, why would you think about wood?”

Wood really has only one advantage over aluminum—a lower initial cost. Beyond that, the advantages of aluminum are impressive:

-

Aluminum ramps can be erected and dismantled quickly and easily with few tools required. Wooden ramps require a skilled carpenter and much more time to build.

-

Unlike a wooden ramp, aluminum ramps are often considered temporary structures, and that can make it easier for them to meet code and permit requirements.

-

Aluminum ramps maintain value. They can be taken down, sold and reconfigured for use elsewhere. They also can be incorporated into rental programs that allow them to be installed and used during relatively short periods of disability, such as that required for recovering from a broken leg. Wooden ramps lack portability.

-

Aluminum ramps are environmentally green since they can be sold as scrap and recycled. Treated wood is fairly toxic.

-

Aluminum ramps are mostly maintenance free. Wooden ramps splinter, crack, require coatings and eventually must be replaced.

Surge in interest

Ramp manufacturers say they are fielding a surge of inquiries from HME providers looking for new products to replace business lost through Medicare’s Competitive Bidding Program. Also, the aluminum ramp business is growing because of the aging baby boomer demographic.

Some HME providers see ramps as a natural, fairly easy business expansion for a company already adept at helping people find solutions to overcome disability or assistance for aging in place.

“It’s a pretty simple business,’’ said MJ Sonnenfeld, VP for marketing and sales at Prairie View Industries (PVI), a ramp maker based in Kansas City, Mo. “It doesn’t take long to ramp-up your expertise.”

In addition to a growing customer base of baby boomers, the downturn in housing prices has convinced many homeowners to stay put and make modifications for aging in place, Sonnenfeld said.

“We’re definitely seeing quite a bit of growth,’’ Sonnenfeld said. “Our demographic is getting older—10,000 Americans each day turn 65.”

Experts say established ramp manufacturers in the U.S. all make good products but differ slightly in finish, service and target market.

For example, American Access has a Wolf Lake collection that offers custom color powder coating that can match a house. “We can also dress it up with a picket railing,’’ Riker said.

The collection is sometimes used for commercial applications and also appeals to customers who have the cash to color their ramp so it blends into the background, she said.

“We have the benefit of having really savvy dealers who have grown the ramp side of their business and are continuing to grow it,’’ Riker said. “For those dealers in that segment, they are seeking out people who have discretionary income, that have the ability to pay for a ramp out of pocket or pay the difference between what the powder coated option would be versus the standard aluminum finish."

Meanwhile, EZ-ACCESS has dropped its powder coat option and replaced it with an aluminum architectural finish that is machined into the metal. It provides an attractive look without the expense of powder coating, Branch said. It appeals to third-party payers who want a high-quality product without frills.

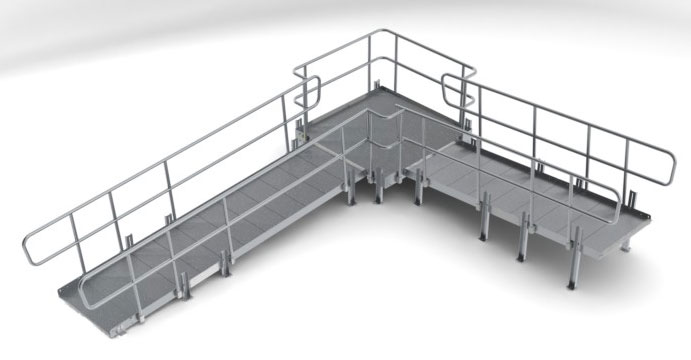

Prairie View Industries focuses on engineering and quality, offering a lifetime warranty. The company has been at the forefront of designing modular ramp systems, Sonnenfeld said. It provides dealers with 3-dimensional CAD drawings that show customers what a PVI ramp looks like in front of their homes.

“In 20 years, we’ve never had a product failure,’’ he said. “We were the original inventor of a lot of the portable products you see out there.”

PVI can custom paint ramps at an in-house powder-coating facility, and all ramps come with a standard white-speckle powder coat finish on the handrails.

Modular designs simplified

All large, aluminum HME-quality ramps can be assembled and disassembled quickly, thanks to modular designs. But it’s a good idea for a provider to find an established manufacturer and develop a long-term relationship, since the products are all different.

“You don’t want to invest a lot in equipment and then not have the company around to take care of that equipment moving forward,” said Branch of EZ-ACCESS. “You can’t take one ramp from one ramp manufacturer and intermix the parts with another.”

With few exceptions, Medicare does not pay for ramps, but private insurers often do, and so does the U.S. Department of Veterans Affairs. Not surprisingly, the baby boom demographic is powering the growth of cash sales in the ramp market.

At EZ-ACCESS, most of the dealers who sell ramps are providers who offer a wide range of HME products.

“Since a lot of our products are sold to third-party providers, you’ll find that a lot of it is done off referrals when it’s done through insurance companies,’’ Branch said. “You have case managers who have a client to take care of for everything from the bed to the grab bar. They’re looking to give the total package to their client. They are hired by the insurance companies to be a one-stop shop.”

It is important to view ramps as part of a holistic approach to HME customers, said Megan Schmit, a marketing associate with EZ-ACCESS. “It’s not all about product anymore,’’ she said. “It’s really about evaluating every situation and providing a solution for every person. As much as there are prefabricated solutions, you’ve got to fit them into a custom situation.’’

Jenifer Burke of AlumiRamp of Quincy, Mich., said her company focuses much time and attention on doing custom ramp work, such as color-match powder coating, crafting unusual angles and building special legs.

AlumiRamp has been around since 1986, a long time for a ramp company, and offers a full line of products. In recent years much of its business has come from supplying ramps for commercial buildings, institutions and ramp rental companies, although AlumiRamp still serves the residential market.

AlumiRamp focuses on quality because, among other things, many of its ramps get long-term, heavy, repeated use, Burke said. Ramps are made from high-quality, heavy-duty, welded and anodized aluminum.

Roll-A-Ramp sets itself apart

One aluminum ramp company sets itself apart from others with a unique design. Roll-A-Ramp of West Fargo, N.D., has a product that does just what its name says—it rolls up.

“It’s always portable,’’ said Greg A. Moll, global business manager. Roll-A-Ramps come in a variety of sizes that can be used for many applications, including van ramps.

Roll-A-Ramp products are all custom-made, but since Roll-A-Ramp is the ultimate in modular design—every small section can be added or removed—that isn’t as big a deal as it sounds. A Roll-A-Ramp product has a fairly high price point, but often, it can be less expensive overall than other ramps because its flexibility lends itself to efficient solutions to ramp problems, Molls said.

Incorporated in 1999, Roll-A-Ramp is a small company that exports about 60 percent of its uniquely designed products. Roll-A-Ramps can be found in places like Buckingham Palace in Great Britain and the Hermitage Art Museum in Russia.

Moll said it’s fairly easy for an HME provider to become a Roll-A-Ramp dealer. It requires a small investment for a display ramp and materials, some education via the Internet and the mechanical ability to use a drill and screwdriver. “It’s not a complicated system to install.”